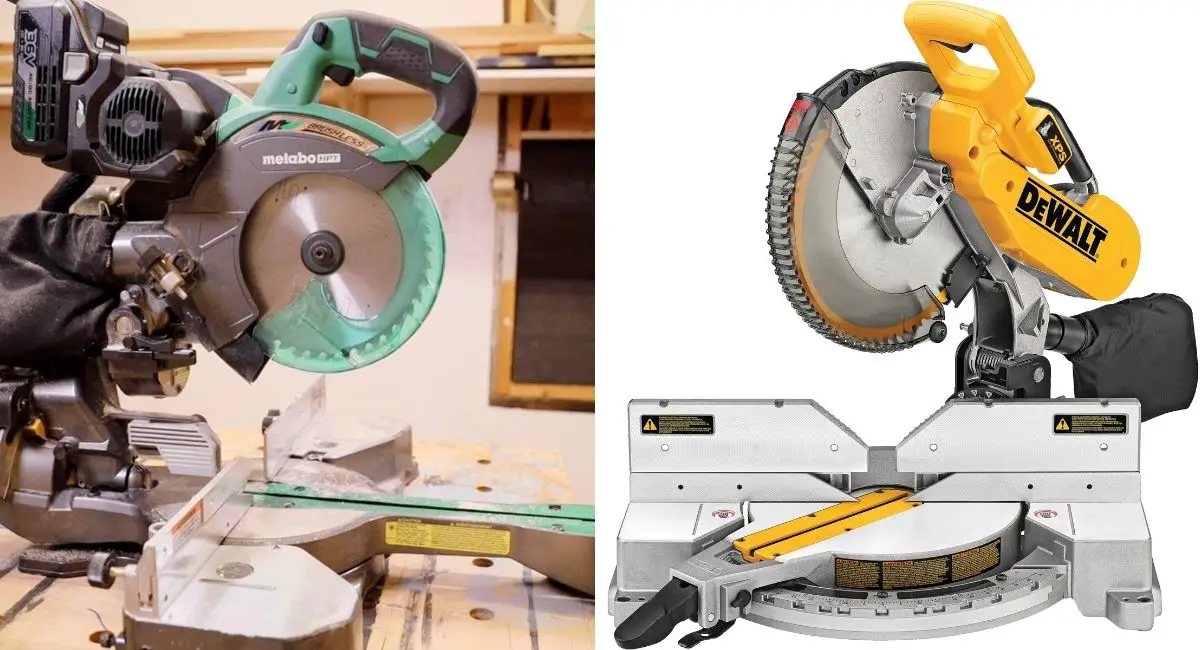

If you’re in the market for a new miter saw, there are two main types of miter saws to choose from non-sliding and sliding. These two categories divide up into more specific models based on their features and capabilities.

A non-sliding compound miter saw has a fixed blade that can be angled to different degrees. A sliding compound miter saw allows the blade (and thus angle) to be changed without unplugging it from its power source.

Sliding miter saws also have dual rails or tracks, meaning they can cut through up to 2″ thick materials.

Some saws have both sliding and non-sliding capabilities, while some are fixed. Most miter saws offer a full 2″ of the bevel- the degree of the arc that the blade tilts in relation to the table.

Sliding Compound Miter Saw vs. Non-Sliding Miter Saw Comparison

Sliding Miter Saw Features

- The dual rail system allows cutting through materials up to 2″ thick. Also known as a double bevel saw.

- Includes auxiliary handles which make adjusting the angle easier and reduce strain on the operator’s arms. These handles attach to either side of the tool for convenience and provide ergonomic support for longer projects.

- The blade can be changed without unplugging it from the saw.

- Compound miter saws have a sliding carriage for changing angles. The carriage is attached to the blade (not the table) and moves on dual rails. When making angled cuts, the blade pivots from its original position against the fence to make the cut.

- This allows for angled cuts that are often difficult to make with a non-sliding saw due to the limitations posed by gravity. Because of this feature, you can use larger blades on compound miter saws than you can with a non-sliding miter saw.

- A compound miter saw is preferable when making a large sequence of repetitive cuts, as it will save time (as opposed to adjusting the bevel angle on a non-sliding saw after each cut.)

- They are also easier to use in instances where materials are too thin to be safely cut with a non-sliding miter saw.

In order to make cuts sideways or upside down, you need a sliding compound miter saw. Otherwise, you would need a different tool entirely.

Non-Sliding Miter Saw Features

- Fixed blade angled at 0 and 45 degrees. The blade cannot be adjusted or replaced unless the entire head is removed and disassembled (extremely inconvenient. Also known as a “mortise and tenon” saw. The blade’s angle cannot be changed or replaced.

- The cutting head can be disconnected from the rest of the tool. This means the saw will not run when disconnected (the days before universal safety interlocks). These saws usually have a locking lever to prevent accidental disengagements, but leave you with only one way to cut properly.

- It only cuts about 1 inch thick (as opposed to 2″).

- Can only be used for cutting mitered joints when mortises are provided in the frame or the material is too thin to make full-depth cuts in it.

- A non-sliding saw is preferred when you need to make a series of repetitive cuts that are all the same angle. A non-sliding saw is not a good option for cutting thinner materials than 1″.

- If working with thin materials, you can use a biscuit joiner to help support them. If you’re cutting from the opposite side of the material, then a sliding miter saw would be more appropriate for your needs.

- If using wood, which naturally expands and contracts as it absorbs moisture, a non-sliding miter saw can be advantageous because it is less likely to shift along with the material as it dries.

- Sliding saws should still be used if working with a material that contracts inwards (such as metal or stone), as they will not expand and contract as much.

- A non-sliding miter saw is best reserved for cutting tenon/mortise joints and only when both pieces are flat and perpendicular to each other, otherwise, the cut will be irregular. In this case, a sliding compound miter saw could be more appropriate.

If you are looking at purchasing a new miter saw, the first question that you need to ask yourself is do you want one with sliding capabilities or not. If the answer is yes, then you may have to prioritize some features over others depending on your intended use of the tool.