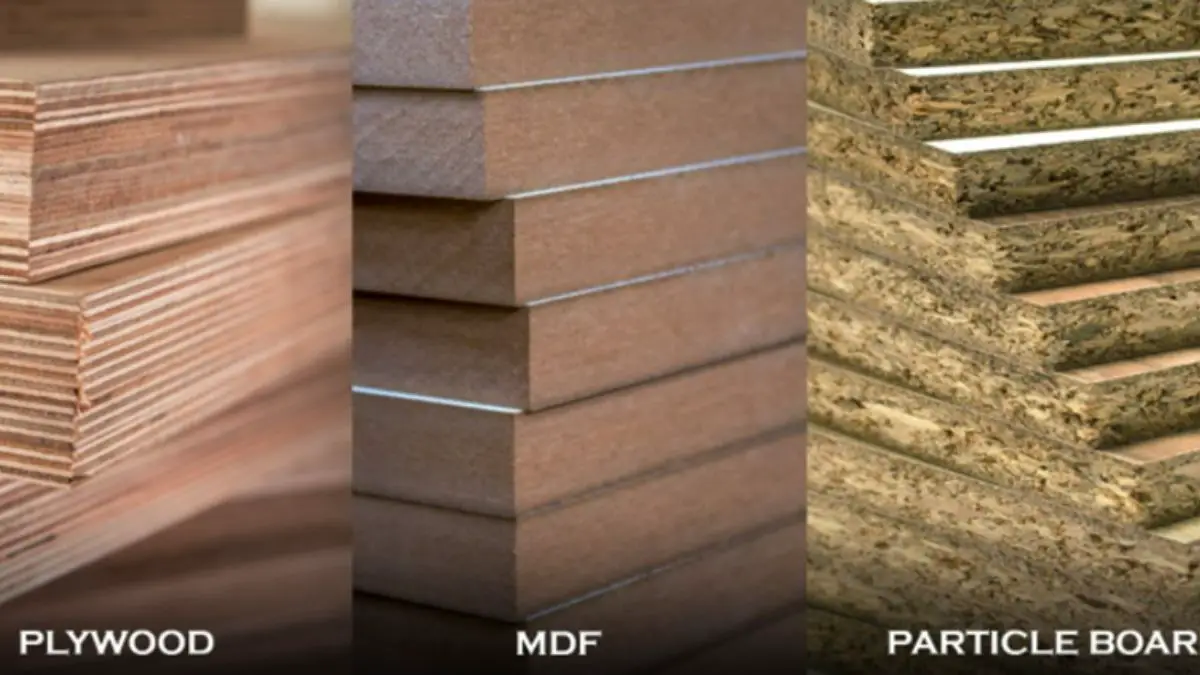

There are many different types of wood, but three of the most common are MDF, particle board, and plywood. So which one should you use? What are the benefits of MDF, particle board, and plywood? Which one is the best for your project?

This post will compare and contrast these three types of wood and help you decide which material is right for you.

Let’s do it!

What is MDF & How is it Made?

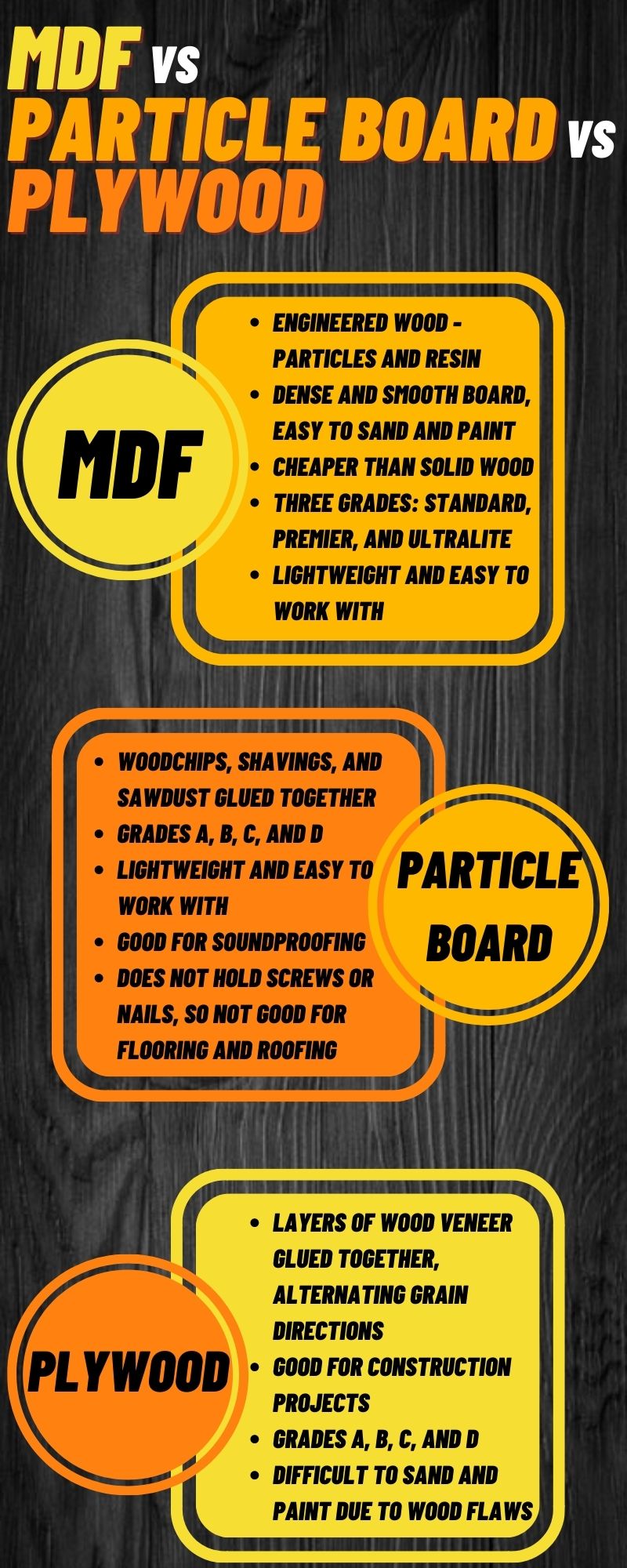

MDF is an engineered wood product composed of hardwood or softwood fibers that have been broken down and combined with wax and a resin binder. It is pressed into sheet form to create MDF boards.

Unlike particle board, which is made of wood chips glued together, MDF is composed of continuous wood fibers. As a result, MDF doesn’t have the same tendency to warp or separate at the seams as particle board.

And because the wood fibers in MDF are so delicate, the surface can be sanded to a smooth finish without creating noticeable wood grain. This also makes MDF easy to cut!

MDF Grades

Not all MDF is created equal. Here’s a quick rundown of the different grades of MDF so you can make the best decision for your needs.

Standard MDF

Standard MDF is the most popular grade and is suitable for most projects. It’s inexpensive and has good dimensional stability, meaning it won’t warp or swell as much as other types of wood when exposed to moisture.

However, it’s not as strong as the other grades and is more susceptible to damage from impact.

Premier MDF

Premier MDF is made from higher-quality fibers than standard MDF, resulting in a stronger, more dimensionally stable product. It’s also the most resistant to moisture damage, making it a decent choice for MDF projects exposed to water or high levels of wear and tear.

However, it’s more expensive than standard MDF.

Ultralite MDF

Ultralite MDF is made from extremely fine wood fibers bonded together using special adhesives. As a result, it’s very strong and dimensionally stable. It’s also the most expensive type of MDF.

Ultralite MDF is often used in high-end furniture and cabinetry, where its superior strength and stability are worth the extra cost.

MDF Uses

- Cabinetry

- Shelving

- Furniture tops

- Molding

- Doors

- Speakers

Pros & Cons of MDF

Some people love MDF, while others aren’t fans – let’s explore the reasons for both!

Pros of MDF

- Denser and smoother than particle board, making it a popular choice for cabinetry, furniture, moldings, and other woodworking projects.

- Less expensive than solid wood and easier to shape with router bits and other tools.

- Lightweight and easy to work with

- Doesn’t distort sound waves like plywood

- Can be easily sanded and painted

Cons of MDF

- Not as strong as solid wood, so it can sag or distort when exposed to humidity or other elements.

- Resin binders in MDF contain formaldehyde, which can harm your health.

- Can harbor mold and mildew because it’s made of wood fibers

- Produces a lot of dust when it’s cut or sanded

What is Particle Board & How is it Made?

Particle board, also known as chipboard, is an engineered wood product made from wood chips, shavings, or sawdust glued together and pressed into sheets.

The density of the particle board can vary depending on the amount of pressure applied during manufacturing. The denser the board, the stronger it will be. Particle boards can be made from various types of wood, including pine, birch, poplar, and maple.

In most cases, the wood chips used to make particle boards are a by-product of other industrial processes, such as sawmilling or furniture making.

Once the particle board has been manufactured, it can be finished with veneer or laminate to give it a smooth surface.

Particle Board Grades

If you’re using particle board to build cabinets or furniture, you’ll want to make sure you select a grade that will give you the results you’re looking for.

Here’s a quick guide to the different grades of particle board.

Grade A Particle Board

The highest quality grade of particle board, grade A is free from defects and is perfect for use in high-end applications.

Grade B Particle Board

A step down from grade A, grade B particle board may have some minor defects but is still suitable for most cabinetry and furniture projects.

Grade C Particle Board

The lowest quality grade of particle board, grade C, is often used for shelving and other non-critical applications. Grade C particle board may have significant defects that can affect its strength and stability.

Grade D Particle Board

Grade D particle board is the lowest grade and is more likely to contain voids, delaminations, and other defects. As a result, it’s not as strong or durable as a higher-quality particle board.

Particle Board Uses

- Subflooring material

- Furniture

- Cabinets

- Shelving

- Acoustic paneling and soundproofing

- Drawer bottoms

Pros & Cons of Particle Board

Particle board has some advantages and disadvantages. Here’s a list of them!

Pros of Particle Board

- Relatively lightweight and easy to work with

- Inexpensive compared to other types of wood.

- Environmentally-friendly

- Smoother surface than plywood

Cons of Particle Board

- Not as strong or durable as solid wood, so it’s more susceptible to damage from moisture and pests

- Doesn’t hold nails or screws, so it’s not recommended for use in load-bearing applications such as roofing or flooring

- Can’t support heavy loads

When choosing particle board for your next project, keep these pros and cons in mind to help you decide if it’s the right material for the job.

What is Plywood & How is it Made?

Plywood is a versatile building material that can be used for a variety of applications. It is made by bonding together multiple layers of wood veneer, with the grain of each layer running in opposite directions.

This provides strength and stability to the plywood, making it an ideal choice for construction projects.

This cross-laminated construction gives plywood exceptional strength and stiffness while also making it resistant to warping and cupping.

Plywood is available in various thicknesses, sizes, and grades, making it ideal for everything from roofing and flooring to furniture and cabinetry.

Plywood Grades

The plywood cost will always be a factor if you require it for your project. Luckily, depending on what you need the plywood for, you can choose different grades according to your budget.

Here’s a quick guide to the different plywood grades available.

Grade A Plywood

Grade A plywood is the highest quality available and is perfect for projects requiring a flawless finish, such as built-ins or fine furniture.

Grade B Plywood

Grade B plywood is also quite nice but may have some knots or imperfections that won’t affect the strength or functionality of the finished piece.

Grade C Plywood

Grade C plywood is functional but could be more attractive and is often used in hidden areas or where it will be covered with another material.

Grade D Plywood

Grade D plywood is the lowest quality and is typically only used for rough construction or where it will be painted.

Plywood Uses

- Construction

- Packaging

- Furniture

- Crafts

- DIY projects

- Kitchen counters

- Sheathing

- Structural framing

Pros & Cons of Plywood

There are some advantages and disadvantages to using plywood that you may not know about. Let’s explore them!

Pros of Plywood

- Relatively inexpensive

- Widely available

- Strong

- More flexible than other wood types

- Can be drilled, screwed, and shaped with relative ease

Cons of Plywood

- Can be vulnerable to moisture damage without sealer or other treatment

- Can sometimes delaminate or peel apart

- Left untreated, it can be prone to discoloration

- Difficult for beginners to saw without splintering

- Difficult to sand or paint

Consider the pros and cons of plywood before deciding if it’s the right material for your next project.

Let’s Recap…

Frequently Asked Questions (FAQs)

Is particle board strong?

While it is not as strong as solid wood, particle board is surprisingly durable and can withstand a fair amount of wear and tear.

Is Ikea furniture particle board?

It depends. Some Ikea furniture is made entirely of particle board, while other pieces have a particle board core with wood veneer or laminate applied to the surface.

Can I paint particle board?

You can paint particle board, but a few things are worth considering. First, particle board is a porous material that absorbs paint unevenly. As a result, you’ll probably need to apply several coats of paint in order to achieve an even finish. In addition, particle board is prone to warping, so it’s important to use water-based paint and ensure that the surface is sanded smooth before you begin painting.

What is better for cabinets, MDF or plywood?

Put simply, cabinets made of plywood are better than those made of MDF. I’ve found that prolonged exposure to moisture in the bathroom or kitchen causes MDF cabinets to swell and screws to become loose.

Is MDF stronger than plywood?

Regarding strength, it’s a matter of which type of strength is more important for your project. If you need a smooth surface that can be painted, MDF is a good choice. Plywood is the way to go if you need something more substantial in tension and shear.

Can I screw into MDF?

The short answer is yes. You can screw into MDF. However, there are three things you need to keep in mind to avoid damaging the material. First, make sure you’re using the correct type of screw. Straight-shanked wood screws are ideal for MDF, as they grip the material without splitting it. Second, predrill pilot holes before driving in the screws. This will help prevent the MDF from cracking. And third, try not to drill or screw too close to the edge. This is one of the most common causes of MDF splitting.