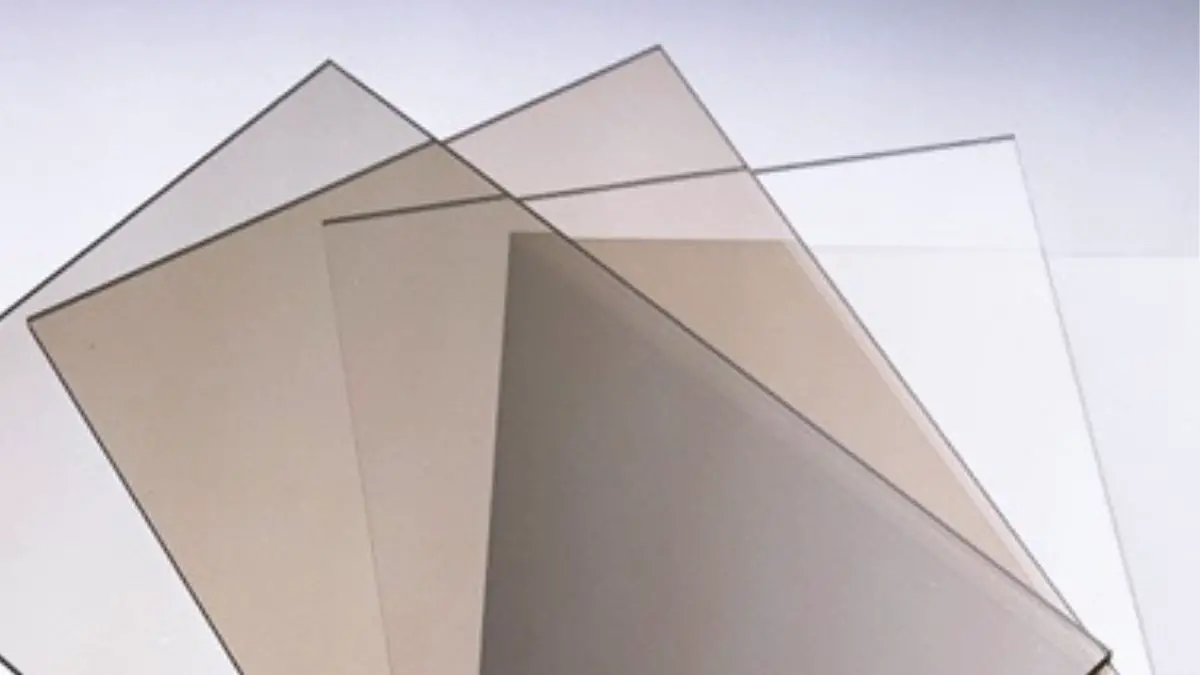

If you’re wondering what the difference is when it comes to Lexan vs. Plexiglass, Plexiglass is a trade name for acrylic glass that is often used to refer to any type of acrylic plastic. Plexiglass is well known for its clarity and toughness.

On the other hand, Lexan is a type of polycarbonate that was originally designed to replace metal windows in automobiles.

Though you can use both materials interchangeably in many cases (i.e. windshields), they each have different attributes that determine which one will work better depending on your project needs.

What is Lexan?

Lexan is a thermoplastic. This means that it’s made from plastic ingredients and then heated and fabricated into a specific shape. Lexan is rigid and strong, especially when made in large pieces.

These pieces often have to be bolted together to make things like signs, displays, or barriers. It’s also used to make car windows because of its strength and transparency. Lexan comes in many varieties of color.

Density: 1.20–1.22 g/cm3

Tensile Strength: 4060 -10900 psi

Elastic Modulus: 2.4 GPa

Maximum Yield Strength: 9500 psi

Thermal Conductivity: 0.19–0.22 W/(m·K)

Typical Uses for Lexan

- Windshields

- Car windows

- Football helmet visors

- Phone cases

- CDs, Blu-Rays, DVD discs

What is Plexiglass?

Plexiglass is made from polycarbonate, a usually transparent material. It’s often used as a substitute for wood or stone because it looks like wood or stone. Plexiglass is also used for signs, car windows, building panels, and other industrial applications.

Density: 1.19 g/cm³

Tensile Strength: 10,000 PSI

Elastic Modulus: 400 – 479 KSI

Maximum Yield Strength: 9400 – 12100 PSI

Thermal Conductivity: 0.17 – 0.19 W/m·K

Typical Uses for Plexiglass

- 3D printing

- Building panels

- Replacement glass for windows

- Protection in sports arenas

- Police riot gear

When Lexan and Plexiglass are made, the raw plastic is poured into large molds. These are then placed in ovens and heated until the plastic has melted.

Then the ovens go into a cooldown process, where they cool depending on how fast they need to cool. The cooled mold then comes out of the ovens and is ready to be trimmed and assembled.

Compared to Lexan, Plexiglass is easier to cut.

Does Lexan scratch easier than Plexiglass?

Lexan is less scratch-resistant than Plexiglass, and it is often difficult to polish out or hide even minor scratches.

What’s cheaper, Lexan or Plexiglass?

While Plexiglass would be cheaper, it does not last as long as Lexan. Lexan is also more durable and scratch-resistant. This makes it better for items that need to withstand harsh conditions like the outdoors or in industrial settings because they won’t break or get scratched.

What temperature does Lexan bend?

Lexan is rigid until it reaches around 170 degrees Fahrenheit. At that point, the plastic becomes more malleable. You should be able to see some changes in the appearance as well.

Is Lexan bulletproof?

By itself, Lexan is not naturally bulletproof. However, when treated with a soft polymer binding agent, Lexan can become a bulletproof material. Exactly how bulletproof Lexan can be will depend on the thickness of the layer and the caliber of the round that makes contact with it.

Is Lexan Polycarbonate?

Yes. Lexan is a Polycarbonate plastic created by DuPont in the 1960s, and its tough, durable nature has made it a popular material used in many products throughout the world.

Is Lexan or Plexiglass better?

Plexiglass can withstand a great deal of force, but Lexan is the stronger and more flexible material. That being said, they’re both ideal for DIY projects. Plexiglass is more often used as an aesthetic choice, whereas Lexan is used when function and high-performance protection are required.