Updated 03/10/2023

Whether you are a DIY enthusiast or an aspiring carpenter, brushing up on your knowledge in every aspect of the business is always a good thing.

From wood to metal and painting to sawing, all your projects can be done in ways that have been tried and tested over the years or even centuries.

So, you need to saw some metal-cutting products to complete your next DIY or carpentry project, but you are not entirely sure about where to begin, and you have a dozen questions about sawing your metals correctly and safely.

Keep reading to find the answers you need before using a scroll saw to cut metal!

What is a Scroll Saw?

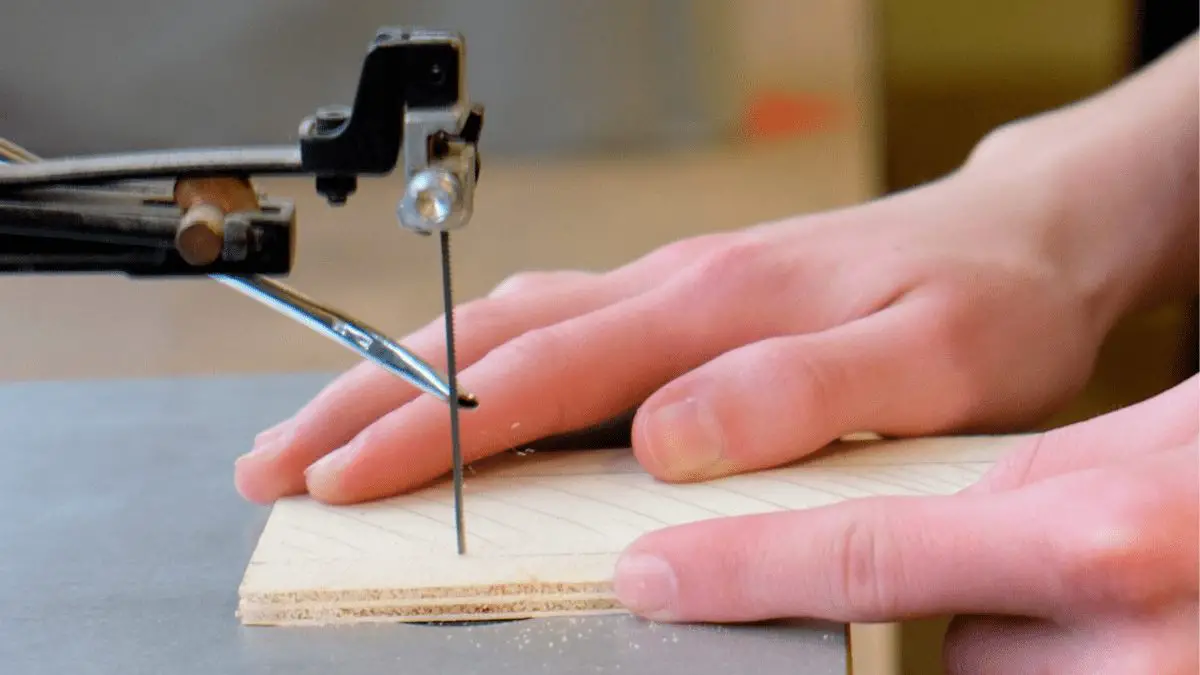

A scroll saw is known for its ability to make very intricate curves when cutting materials such as wood, EVA foam, metal, plexiglass, and a variety of other materials.

The scroll saw is equipped with a very fine blade, enabling the saw to cut delicately and more easily, compared to power jigsaws and hand-coping saws.

Being able to pivot the table gives you the ability to create curves along your cutting edges.

A scroll saw was traditionally used to make scrollwork (a form of sculptural artwork) and ornaments.

Thus, the saw was given its name: the scroll saw.

What Blade Do I Need to Use for Sawing Metals?

Starting your project with the right blade is ideally your first step in the cutting process.

The most important rule here is to never- that’s right, you heard me- never use a wood cutting blade because metal materials can ruin the teeth, and you will never be able to use that blade again.

Instead, we recommend that you purchase a metal cutting blade.

They have specialized, hardened teeth that allow you to cut through metals easier, without destroying your wood-cutting blades one at a time.

These metal-cutting blades are available in various sizes that can be used for anything from fine jeweler blades to capable of heavy-duty tasks.

Do I Need a Lubricant When Sawing Metals?

Whether or not to use a lubricant when sawing your metal will depend on the type of metal with which you are working and the type of blade you have chosen.

Some metals, usually the softer ones like brass, copper, and gold, will cut easily without a lubricant or oils.

On the other hand, harder metals like aluminum cut much easier when a lubricant is used.

The purpose of using a lubricant is to reduce friction between the metal you are cutting and the blade and reduce the heat generation caused by the friction.

The type of lubricant you must use will be dependent on the metal you are cutting. Lubricants come in a variety of forms, tailored to your specific needs.

How Does Cutting Various Metals Differ?

It is possible to cut harder metals with a scroll saw; however, it is very difficult.

Therefore, it is advised that harder metals should not be cut using a scroll saw.

Should you wish to take on the challenge, use the saw on a low-speed setting, and the blade is adequately lubricated.

Work slowly as you feed the metal through the blade. If you need to cut a hard metal that is thicker than half an inch, find another saw to tackle the task.

What Types of Metal Can Scroll Saws Cut?

The most common metals used in scrollsaw projects are aluminum, brass, and copper. Aluminum is a highly malleable metal that can only be cut with special blades.

Brass is an alloy of copper and zinc. It is stronger than pure copper in the right proportions and less malleable.

It also requires special blades to cut through it without breaking the blade when it does not bend as a regular steel blade would.

Copper is one of the most common metals you will use to make things with a scroll saw, like jewelry, because its high malleability makes it very easy to work with and creates designs with lots of detail.

In addition to those metals, a scroll saw can also cut through steel, bronze, and gold. Steel is a tough metal most often used for armor or weapons.

Bronze is an alloy of copper and tin with many art applications.

Gold is a soft precious metal that can be worked into intricate designs as long as it remains pliable enough during cutting.

Materials like titanium, stainless steel, or other foreign materials will require special blades to cut them and may also be very difficult to cut through due to the harder material.

How Do I Protect My Metal While Sawing?

Sawing through a piece of metal can become a messy business. You want to protect the metal as you saw through it, since burring along the bottom may occur.

You can prevent this burring by placing the metal between two pieces of plywood like a sandwich before you cut.

This will also prevent pieces of metal from flying around while you are working.

How Do I Ensure My Safety When Cutting Metal?

Statistics show that the DIY revolution has seen an increase in tool-related injuries. Therefore, it is important to ensure you have all the necessary safety precautions before you begin.

The most obvious precaution is wearing safety glasses to protect your eyes from flying debris during the sawing process.

Secondly, clamp your materials down, so that you can have full control of your saw with both hands.

Also, ensure that there are no other objects in the way of your sawing area. You don’t want to accidentally saw into something you should not.

Before you begin your next metal project, be sure to check up on all the relevant aspects before you start.

Ensure you have the correct blades and other supporting tools that you will need to complete the task.

Find the correct lubricants, and use them when necessary to ensure a flawless cutting process.

Also, follow the correct procedures for the type of metals you need to saw.

Lastly, take all scroll saw safety precautions seriously to prevent any mishaps or injury while completing your DIY or carpentry projects.